In the steel manufacturing industry, scrap metal recycling is an integral part of the new product development process. Proper management of the material boosts the companies’ operating indicators. As well as quality to the highest international standards.

Due to the advance of technologies in the last years, the steel industry and the industry in general, is making a 180-degree turn with the integration of artificial intelligence in its operations.

In Tecnoap, a company with 30 years of experience in the steel manufacturing sector, we have launched SCRAPYARD®. SCRAPYARD® is a platform immersed in the context of the entry of ferrous scrap to steel mills, which use this scrap as raw material for the manufacture of steel for various industrial uses.

WHAT IS SCRAPYARD® AND WHAT ISSUES DOES IT ADDRESS?

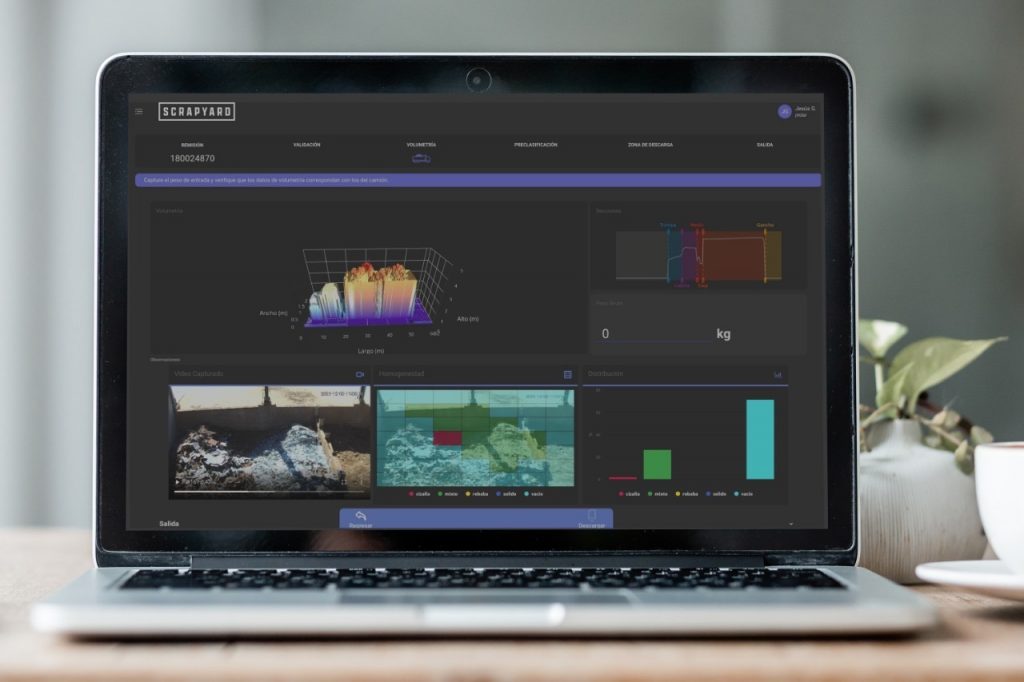

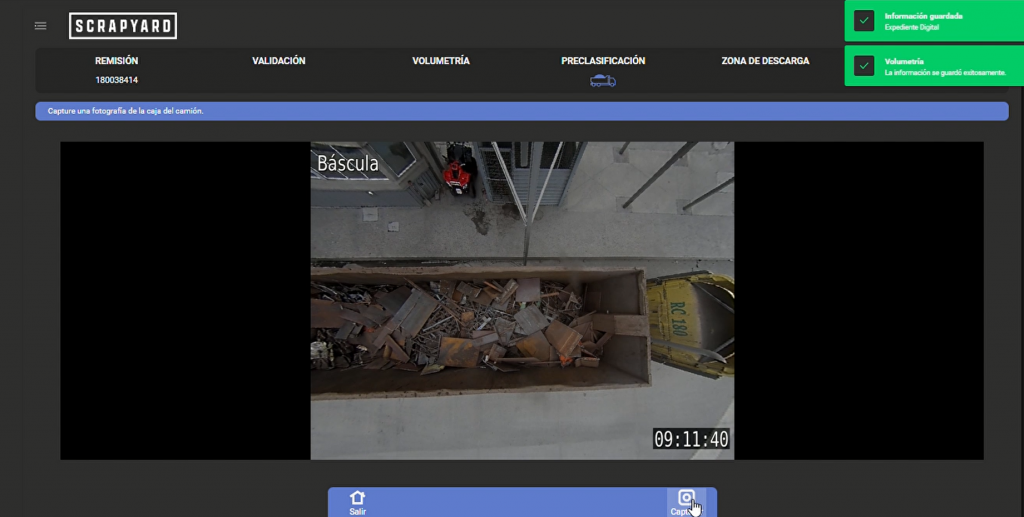

SCRAPYARD® is a web platform focused on the management and classification of scrap metal using Artificial Intelligence, sensors and machine learning.

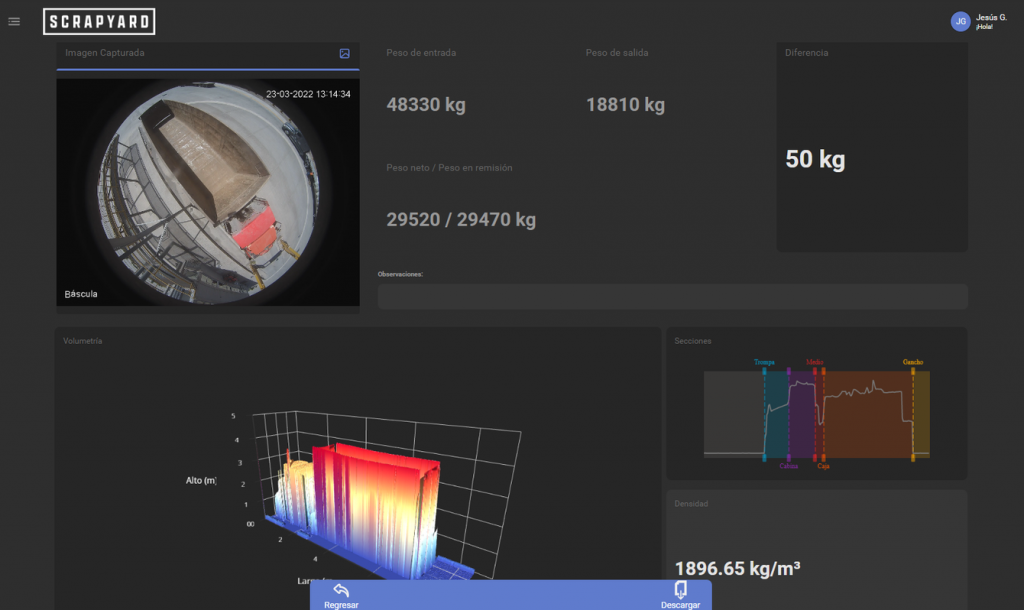

The problem that addresses is the management of the reception of trucks loaded with scrap metal from both internal and external suppliers. The validation of the weight of the load, the automatic classification of the type of scrap metal through vision analytics, registration of the physical location where it is unloaded and the calculation of the density of the load. All this information is an important factor in determining the quality of suppliers and their payment.

Thanks to SCRAPYARD®’s intelligence, the objectivity and transparency of the processes of receiving, sorting and unloading scrap within the facilities are guaranteed. Thus, a digital file is generated for each entry with all the information provided by the supplier, automatically captured, and generated by the platform. In addition, all the information generated can be used for auditing purposes, since the process is totally reliable and transparent.

WHICH IS THE PURPOSE AND HOW IS DENSITY MEASURED WITH SCRAPYARD®?

Information generated by sensors and Artificial Intelligence can be combined to improve accuracy and efficiency in the measurement and analysis of volumetric data. Artificial Intelligence, through machine learning and image processing techniques, can automatize and accelerate the density measurement process. This can save time and reduce human mistakes.

Thanks to the SCRAPYARD®’s volumetry module, the scrap density factor can be incorporated as a variable to implement new payment models to buyers. As Wellington as to improve the determination of scrap batches to be introduced into the furnace with the objective of introducing “certified loads” into the furnace.

The obtained information in this module allows you to classify your suppliers in a leaderboard and organize your scrap metal yard according to densities.

In a first instance, a line of trucks charged with scrap metal are waiting to enter the plant to be unloaded. For each truck that enters the plant, an instance or workflow is created, which stays active until it leaves the plant, after having completed a series of well-identified steps. For this specific module, the following scrap entry processing steps are required.

- Information validation. This is done by the verification of the in-process shipment against the truck data, supplier, carrier and load data.

- Volumetrics. A process that receives the truck’s height and speed data from other components, which is used to calculate the volume of the truck’s load.

- Weight capture. Integration with the scale through a communication driver for the automatic capture of the truck’s weight.

Once all phases have been completed, the truck leaves for the entry/exit shed. Once there, the sensors and cameras perform a new complete sweep of the empty truck, determining the floor plan of the truck’s box and consequently the volume of the box to be deducted from the volume previously obtained during the entry. In this way it is possible to calculate the volume of the incoming charge. Later, the tare weight of the truck (empty weight) is measured, which makes it possible to calculate the weight of the delivered load and the corresponding density of the scrap.